GRK 2193

The Research Training Group “Adaption Intelligence of Factories in a Dynamic and Complex Environment” offers the opportunity to conduct joint research about adaption planning and realisation of factory systems. In the context of increased dynamics and intensive transformation processes within industrial environments, the ability of factories to adapt to these changes has becomes more and more necessary.

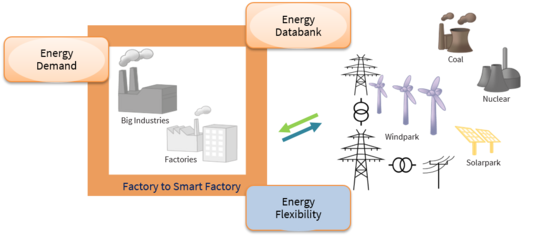

Progressively, the focus on the fourth industrial revolution has reignited the need for energy efficient manufacturing. The industrial sectors, who are the largest consumer of electricity, has to improvise on the energy efficiency of their respective production processes. This raises vital problems in energy monitoring and optimization of individual production systems. In particular, industrial machines with greater adaptability has opened up an intriguing possibility to examine their power consumption as well as to determine their suitability for energy efficient manufacturing. In addition, the energy demand of factory machines along with its occupancy time in a factory floor poses challenges to energy supply grid and subsequent effects on energy flexibility.

With increasing utilization and tight integration of renewable energy sources, it has become necessary to determine and analyse the energy demands of machines beforehand as well as to optimize power flexibility accordingly. There already exists methods to determine the key performance indicators with respect to the energy efficiency of the industrial processes. However, digitalisation and advancements in Internet of Things has opened up to huge availability of raw data from factory machines and subsequent possibilities to design detailed energy consumption models of various processes. This requires processing big amount of data with higher accuracies in an intelligent and adaptive manner, possibly using Artificial Intelligence.

Project duration: 04/2016 - 03/2025

Project Website: https://www.grk2193.tu-dortmund.de/

Project Partners

TU Dortmund Institute Partners

Institut für Energiesysteme, Energieeffizienz und Energiewirtschaft (ie3), Prof. Dr.-Ing. Christian Rehtanz | Lehrstuhl Unternehmensrechnung und Controlling, Prof. Dr. Andreas Hoffjan | Lehrstuhl für Software Engineering, Prof. Dr. Jakob Rehof | Lehrstuhl für praktische Informatik, Prof. Dr. Peter Buchholz | Sozialforschungsstelle Dortmund, Prof. Dr. Jürgen Howaldt | Lehrstuhl für Unternehmenslogistik, Prof. Dr. Michael Henke | Lehrstuhl für Software Engineering, AG „Virtual Machining“, Prof. Dr.-Ing. Petra Wiederkehr | Institut für spanende Fertigung, Prof. Dr.-Ing. Prof. h.c. Dirk Biermann | Lehrstuhl für Unternehmenslogistik, Prof. Dr. Michael Henke | Digitalisierung in Unternehmenslogistik und Supply Chain Management, Lehrstuhl für Unternehmenslogistik, Jun.-Prof. Dr.-Ing. Anne Meyer | Lehrstuhl Baubetrieb und Bauprozessmanagement, Prof. Dr. Mike Gralla | Lehrstuhl für Förder- und Lagerwesen, Prof. Dr. Dr. h.c. Michael ten Hompel

External Institute Partner

RIF Institut für Forschung und Transfer e.V. (RIF e. V.), Prof. Dr. Jürgen Roßmann

Scientific Partners

Forschungsgebiet Industrie- und Arbeitsforschung, TU Dortmund, Prof. Dr. Hartmut Hirsch-Kreinsen | Datalogisk Institut, Algorithms and Programming Languages Section (APL), University of Copenhagen, Denmark, Prof. Dr. Fritz Henglein | Tongji University, Shanghai, Chinesisch-Deutsches Hochschulkolleg (CDHK), China, Prof. Dr.-Ing. Dianjun Fang | Leistungszentrum Logistik und IT, Dortmund, Dr.-Ing. Christoph Besenfelder, Christoph Pott | Fraunhofer Institut für Materialfluss und Logistik IML, Dortmund | Graduate School of Logistics (GSofLog), Dortmund

Industrial Partners

Joyson Safety Systems | TRUMPF Werkzeugmaschinen GmbH + Co. KG | ipolog GmbH

Sponsors